Removing the hatch took several hours to break the aluminum frame from the rise as well as breaking the riser loose from the actual deck. Both had to be removed to inspect the core where the leak was. We do have softened core in a small section along the opening, it is being removed and filled with a thickened epoxy.

The deck around the openings have all been cleaned and all silicone and adhesive removed. Acetone worked well along with some 3M pads and razor blades for removing the material.

All of that was going according to plan, what was not going according to plan was noticing down below that water was slowly coming in along the forward port chainplate. (The Chainplates are what attach to the hull and then the Standing Rigging, the wire that holds up the mast, is attached to).

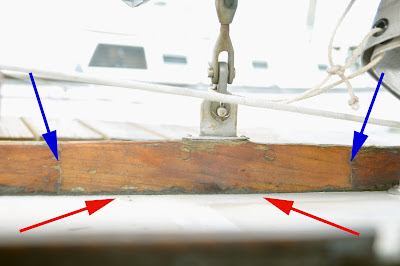

All of that was going according to plan, what was not going according to plan was noticing down below that water was slowly coming in along the forward port chainplate. (The Chainplates are what attach to the hull and then the Standing Rigging, the wire that holds up the mast, is attached to).After further inspection, I can see that at some point in time, this chain plate had some type of service done to it. The wooden toe rail that the chainplate goes through, has been cut and then patched back in. (Below in the image, the blue arrows point to the spot where the toe rail had been cut to gain access to the chainplate. The red arrows point to the spot that the water is getting into. I noticed when pouring just a couple of ounces of water on the deck in front of that patched part of the toe rail, some of it is running in.) I could likely just run a bead of silicone along the joint between the toe rail and the deck, but I suspect that if this has been leaking for a while, I really want to see what is going on in there where that patch is. This is one of the benefits of having the boat down to bear hull. I would have never seen this otherwise and in the end, it is not a lot of water coming in, but a little bit every day would cause serious damage. Now I know why I am having to replace the wooden countertop in the Salon, I suspected a leaking port, but I don't think that is the bigger problem here.

The strange thing is that it was not raining, this leak became evident just from the dew that was on the deck and starting to pool along the edge of the patched part of the toe rail. Needless to say, I will be removing the patch and inspecting this closer. This is a delay I certainly did not anticipate.

I am starting to see why I have heard that when starting a boat project, estimate the time line and the cost accurately and realistically, then double the cost and triple the time and you will be about right for the job. That has certainly proven to be the case in most of our ventures so far. :) Ahhh boat ownership. I joke, but really wouldn't trade it for the world.